U shape auto duct line 5 - Preda Machine

U shape auto duct line 5 - Preda Machine

U shape auto duct line 5 - Preda Machine

- Detail

- Parameters

- Review

Product Description

U shape line auto duct line 5 is a most cost efficient full auto duct forming line with the duct formed automatically from decoiling to a formed squared duct!

Every step could be controlled by putting parameters into Mitsubishi PLC screen.

Having an auto duct line is a magnificent sign of scaled HVAC duct factory in the whole world!

Main Import Configuration:

1) MITSUBISHI HMI Display And PLC;

2) MITSUBISHI Frequency Converter;

3 )Japan NEMICON Inverter;

4 )Taiwan Hydromax Pump;

5) Taiwan High Temperature Resistant Tubing.

Basic Configuration:

1. Two electric coil cradles, 4 material trays (5-7t each roll);

2. One rack;

3. One host (line 2 host);

4. One mechanical arm clutching, locating and transferring platform;

5. One displacement type locking machine;

6. One duplex TDF flange forming machine;

7. One duplex angle steel flange forming machine;

8. One servo feeding platform;

9. One hydraulic folding machine;

10. One set of computer controlling system.

Model | Thickness (mm) | Max width (mm) | Working speed (m/min) | Weight of coil (T) | Dimension (mm) L*W*H | Power (kw) | Weight (T) |

AML-U5-1300 | 0.5-1.2 | 1300 | 0-23 | 7 | 14000*5000*1350 | 7 | 3 |

AML-U5-1500 | 0.5-1.2 | 1500 | 0-23 | 7 | 14000*5000*1350 | 8.5 | 3.2 |

More About U Shape Auto Duct Line 5

Preda Machine auto duct line is a automatic rectangle pipe production line. The auto duct line has combined with excellent technical content at home and abroad. It owns MITSUBISHI HMI Display And PLC&MITSUBISHI Frequency Converter&Japan NEMICON Inverter&Taiwan Hydromax Pump&Taiwan High Temperature Resistant Tubing.And the auto duct line can produce a complete rectangle duct separately. Auto duct line is the best helper in pipe making machinery when you produce pipe.

U shape auto duct line also saves a lot of space in the site occupancy, and U shape auto duct line's production speed far exceeds the ordinary production line. When you ready to purchase a pipe production line,Preda Machine U shape auto duct line is a best chose for you!!

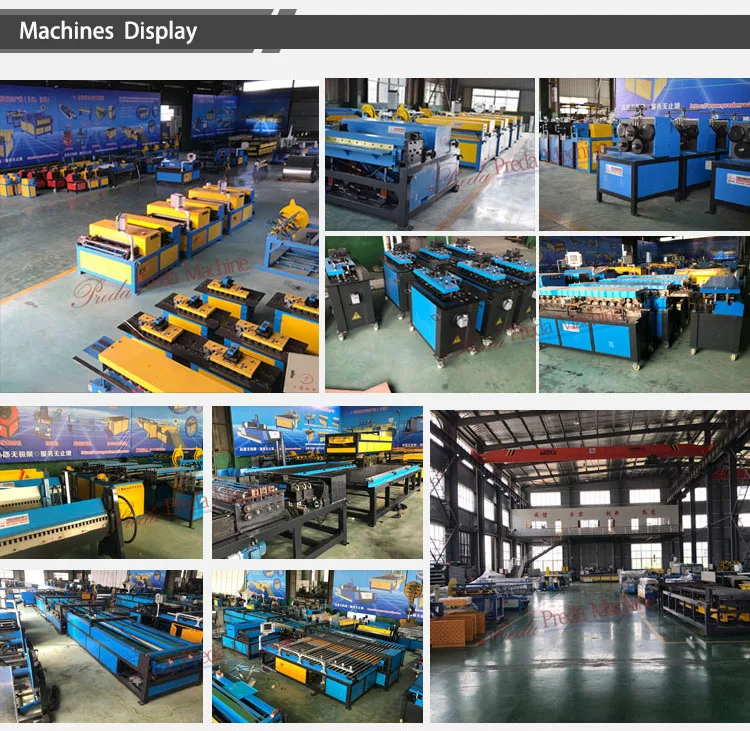

Anhui Preda Machinery Manufacturing Co., LTD. is a manufacturing company. Our company is committed to the production of HVAC duct production machines. Our company has more than 10 years of production and export experience. Anhui Preda Machinery Manufacturing Co.,LTD is located in Hongyang Industrial Park, Bowang Town, Bowang District, Ma'anshan City, Anhui Province, China. It is only 20 kilometers away from Nanjing International Airport, which also facilitates customers from all over the world to come to our factory to have a convenient face-to-face conversation and visit.

We manufactured and exported auto duct lines, CNC plasma cutting machine, TDF flange forming machine, pittsburgh lock forming machine, spiral duct forming machine, elbow making machines, TDC flange forming machine, oval duct forming machine and so on. All our machines are popular in the ventilation pipe manufacturing industry. We also exported CNC hydraulic press brake machine, CNC hydraulic shearing machine with factory price and best quality. All of our duct machines are in stock, we will manufactured the most of standard commonly used machine as inventory, so if our customers need, we will arrange delivery all the time.

We also have our after-sale servie teams, we support our engineers overseas service. When you met the problems, we will help you solve the problem in time, and all the machines we will have a lifetime warranty. We use our sincerity to serve our customers and expect more customers to choose Anhui Preda Machinery Manufacturing Co., LTD.

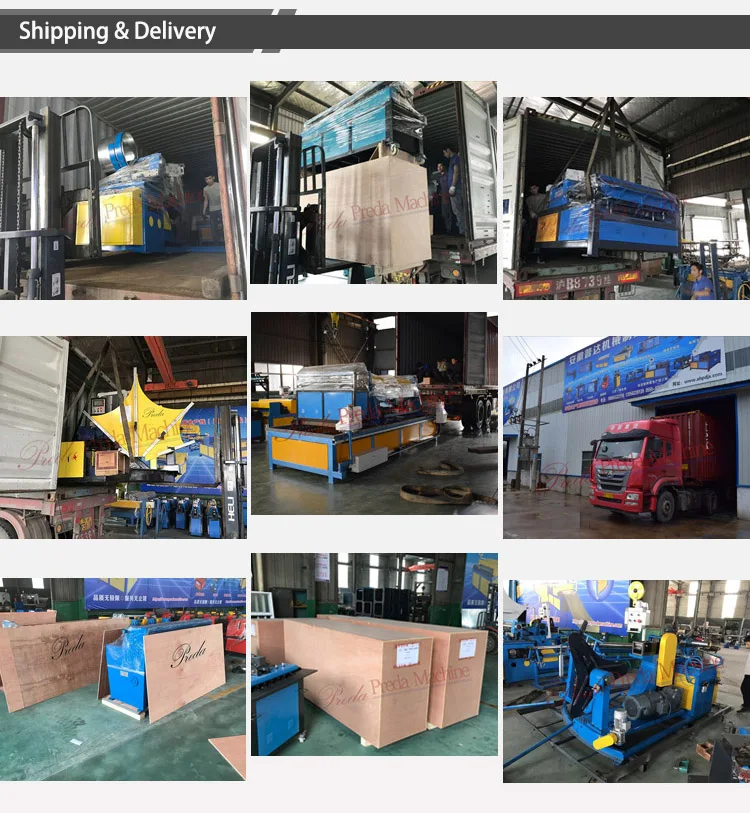

Delivery details

Customers purchase our auto duct lines and we will ship them through containers. The auto duct line 3 and the aut duct line 2 will be transported through the 20' container, and the auto duct line 5 and U-shape auto duct line will be transported through the 40' container. CNC plasma cutting machine will also be transported through the 20' container. All machines transported through the container are inside the container which we will pull the two sides of the machine with thick wire ropes and hooks so that they do not shake during shipping and cause the machine to collide. A certain amount of movable space is reserved between the machine and the machine to ensure that the machine is intact when it reaches the customer's factory.

The packaging of small machines such as the duct TDF flange forming machine, the pittsburgh lock forming machine, and the elbow making machine will be packed in wooden cases. The chassis is welded by channel steel and the bottom is reserved for 10cm for easy loading and unloading. It will be fixed with wooden boards around to avoid collisions during transportation.

1. How to get a accurate quotation from Preda Machine?

Provide the machine name you want, the specifications you need and the quantity of machine, we shall quote accordingly!

2. What's the shipping cost from China to your country?

Please kindly tell us your nearest port to your place. We have reliable shipping forwarder to insure cheap, safe, convenient and timely delivery via sea.

3. Payment terms, MOQ, warranty, FOB.

Payment terms: 20% TT paid in advance, the balance of 80% before the shipment.

Minimum order quantity: 1 set of any machine of Preda Machine.

Delivery time : 5days after order confirmation. As a real manufacturer, we normally stock our machine in at least 5-10 sets including auto duct line 5, auto duct line 3, auto duct line 2!

And at least 20 sets each for TDF flange forming machine, Pittsburgh lock former, TDF folding machine, Pneumatic folder and etc...

Shipping terms : FOB, CFR, CIF and etc.. according to your requirements.

Warranty:24 months after our machines arriving at you.

4. What's the package?

Fumigation-free plywood case for LCL and nude package for full container basis such duct production line 5, duct auto line 3, duct line 2...

5. What about commissioning service?

We can offer commissioning service, the buyer need to pay for all the transport, salary, hotel, meals for Preda Machine technicians caused during the service period.

6. What's policy for guarantee and broken parts?

Warranty period of equipment is two years, during which the broken parts and spares caused by quality can be offered free. After guarantee period, all broken parts or easy wearing parts will be charged in a most competitive price ever in the market!

Precautionsand trouble shooting solutions for air duct production line 5 U shape!

Before using the Preda Machine auto duct production line 5 U shape, you should read the instruction manual and other relevant materials carefully in order to properly operate the auto ductproduction line 5 U shape, and pay attention to the following points:

(1) Machine tool operation and maintenance personnel must be professionals who have mastered the relevant machine tool before

with professional knowledge or technically trained personnel, and must operatethe machine tool in accordance with safe operating regulations;

(2) Non-professionals are not allowed to open the electric cabinet door.

Before opening the electric cabinet door, make sure that the main power switch of the machine tool is turned off.

Only professional maintenance personnel are allowed to open the cabinet door for power-onmaintenance,

(3) Except for some parameters that can be used by the user and can be changed, other system parameters,

spindle parameters, servoparameters, etc., cannot be modified by the user without permission,

otherwise the operator will be injured by equipment, workpieces, or other personal injury.

(4) After modifying the parameters, before the first processing is performed, no-load test operation without loading the raw materials is required.

After confirming that the auto duct production line 5 is all running well, the raw materials can then be loaded and used for production;

(5) The PLC program of the machine tool is designed by Preda Machine according to the needs of the auto duct production line 5

and does not need to be modified.

Incorrect modification, operation of the machine tool may cause damage to the machine tool and even hurt the operator;

(6) If the continuous running time of the machineis too long, it will affect the life of the electrical system

and some mechanical components, which will affect the accuracy of the auto duct production line 5U shape.

It is recommended that the continuous working time does not exceed 8 hours.

(7) All connectors, joints, etc. of the Preda Machine auto duct production line are not allowed to be unplugged or plugged inunder power,

otherwise serious consequences will be caused.