CNC hydraulic shearing machine -Preda Machine

CNC hydraulic shearing machine -Preda Machine

CNC hydraulic shearing machine -Preda Machine

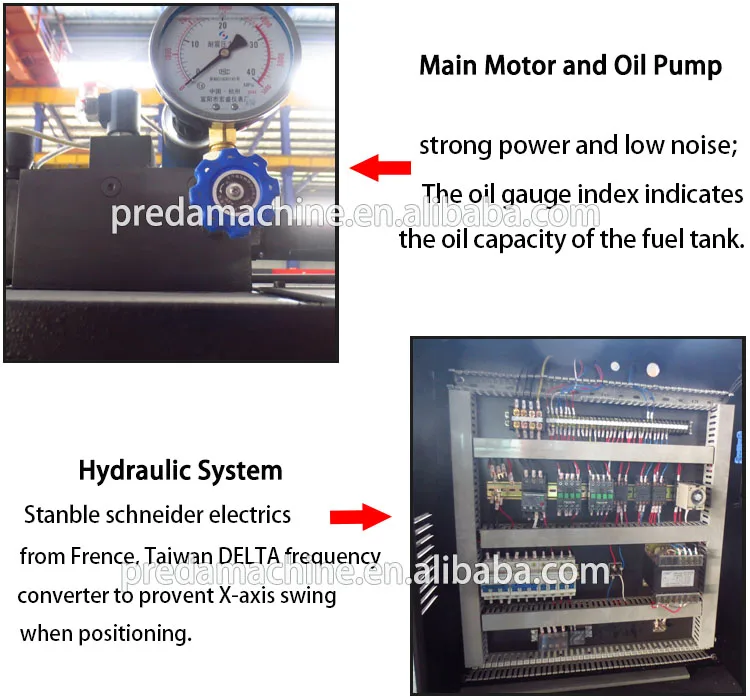

- Detail

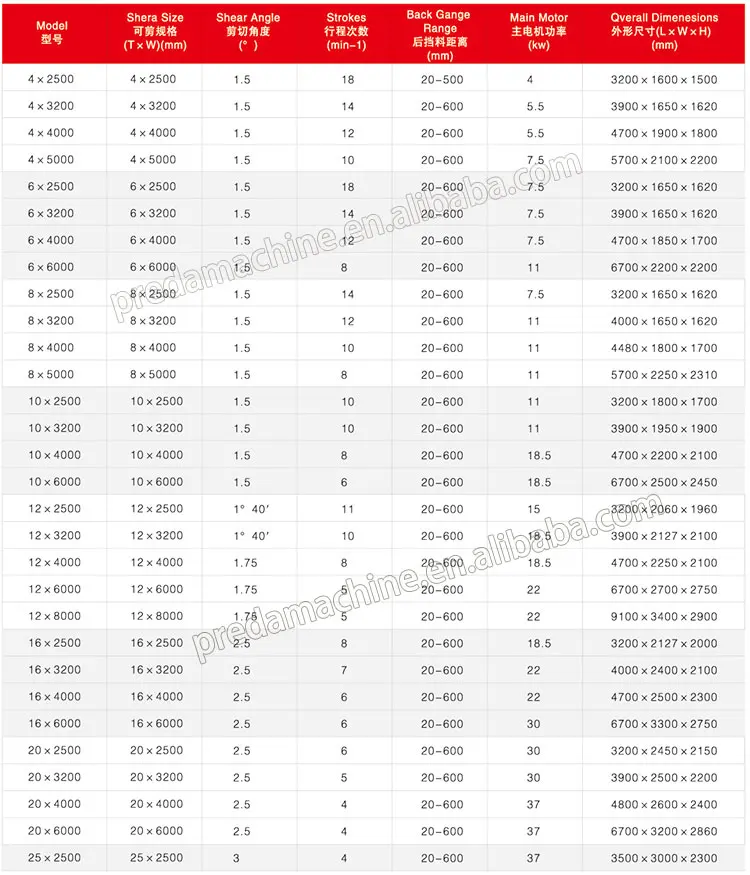

- Parameters

- Review

Product Application

The hydraulic shearing machine is machine that uses a reasonable blade gap to apply a shearing force to various thicknesses of sheet metal by means of a moving upper blade and a fixed blade gap to break the sheet at a desired size.

Shearing machine is a kind of shearing equipment widely used in machining, which can cut steel plate materials of various thicknesses. Commonly used shearing machines are divided into three types: flat shear, rolling shear and vibration shear. The flat shears are used in large quantities. Shearing machines with a thickness of less than 10 mm are mostly mechanical transmissions, and those with a thickness greater than 10 mm are hydraulically driven. Single or continuous shearing of the metal is typically performed using a foot or button manipulation.

Standard Equipment

a.HONGKONG MD11 NC control System/Estun E21S NC control System;

b.High quality cutting blade(6CrW2Si);

c.Siemens Main Motor;

d.Germany supplier Hydraulic;

e.Hydraulic &Electrical overload protection for necessary;

f.Germany EMB Tubing connector;

g.Automatic back gauge feeding device.

Main Features

1. The hydraulic shearing machine body is welded with high-strength steel plate, and the body is stable. With hydraulic drive and accumulator, equipped with numerical display system numerical control device, easy to operate and reliable performance.

2. The blade gap can be adjusted through the display to facilitate quick adjustment of the blade position.

3. Provide rolling material to support the ball to reduce the generation of residual material and reduce frictional resistance.

4. The back gauge is equipped with an encoder and a digital display system. The staff can accurately know the position of the back material, which further improves the cutting precision of the machine.

Safety Technical Requirements for Hydraulic Shearing Machine

(1) Before work, it is necessary to carefully check whether the various parts of the shearing machine are normal, whether the electrical equipment is intact, whether the lubrication system is unblocked, and the tools and measuring tools such as tools and measuring tools and corner scraps are placed on the surface of the table.

(2) do not operate the shearing machine by one person alone, should be coordinated by 2-3 people to carry out feeding, control dimensional accuracy and reclaiming, etc., and be determined to be unified by one person.

(3) Adjust the scissors gap of the shearing machine according to the specified thickness of the shearing plate. It is not allowed to cut two kinds of sheets of different specifications and different materials at the same time; The cut sheet requires a flat surface and is not allowed to cut narrower sheets that cannot be pressed.

(4) Protective covers must be installed on the moving parts of the belt, flywheel, gears and shafts of the shearing machine.

(5) The finger fed by the shearing machine operator should keep a distance of at least 200mm from the scissors opening and leave the pressing device. The protective fence placed on the trigger can't block the operator's eyes and can't see the cut. The waste generated after the operation is angular and the operator should remove it in time to prevent stab wounds and cuts.

Maintenance

1. Operate in strict accordance with the operating procedures.

2. Before starting the machine, press the lubrication chart to check the timing, fixed point and quantitative lubrication. The oil should be clean and free of sediment.

3, the machine tool must always keep clean, unpainted part of the anti-rust grease.

4. Lubricating oil in the motor bearing should be replaced regularly, and often check whether the electrical part is working safely and reliably.

5. Regularly check whether the V-belt, handle, knob, and button are damaged. If the wear is serious, it should be replaced in time, and the spare parts should be replenished.

6. Regularly check the repair switch, insurance, and handle to ensure reliable operation.

7. 10 minutes before work every day, lubricate the machine and lubricate the machine.

8. It is strictly forbidden for non-designated personnel to operate the equipment. It is usually necessary to stop people from leaving the aircraft.

The transport cost as reference please contact us to get more clearly transport cost directly. Different port of countries will have different cost!

Anhui Preda Machinery Manufacturing Co., Ltd. is a manufacturing plant, and produces and sells machinery, machine tools, machine tools, machine tools and machinery parts. It has many years of production experience and export experience. The products are sold to Europe, Middle East, Asia, etc. Countries in each region are unanimously recognized by customers.

Our company's equipment includes ventilation equipment, hydraulic shearing machines, bending machines, punching and shearing machines and other equipment for industrial production. A wide range of products to meet the different needs of customers also supports the customization of personalized machines according to customer requirements.

| FAQ |

| 1. How to get a accurate quotation from Preda Machine? |

| Provide the machine name you want, the specifications you need and the quantity of machine, we shall quote accordingly! |

| 2. What's the shipping cost from China to your country? |

| Please kindly tell us your nearest port to your place. We have reliable shipping forwarder to insure cheap, safe, convenient and timely delivery via sea. |

| 3. Payment terms, MOQ, warranty, FOB. |

Payment terms: 20% TT paid in advance, the balance of 80% before the shipment. |

| 4. What's the package? |

| 20'' container, 40'' container, wooden case, wooden tray.... |

| 5. What about commissioning service? |

| We can offer commissioning service, the buyer need to pay for all the transport, salary, hotel, meals for Preda Machine technicians caused during the service period. |

| 6. What's policy for guarantee and broken parts? |

| Warranty period of equipment is two years, during which the broken parts and spares caused by quality can be offered free. After guarantee period, all broken parts or easy wearing parts will be charged in a most competitive price ever in the market! |