Duct beading machine 1300mm with 5 grooves - Preda Machine

Duct beading machine 1300mm with 5 grooves - Preda Machine

Duct beading machine 1300mm with 5 grooves - Preda Machine

- Detail

- Parameters

- Review

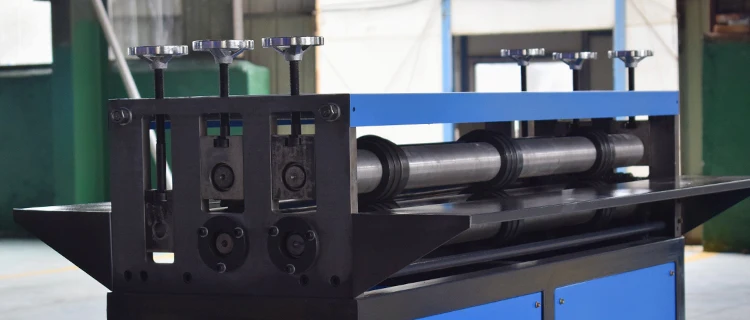

Duct beading machine.

Product Application

Duct Beading Machine is used to form beads on flat sheet metal for stiffening ductwork and fittings.

Beading rolls are designed for easy replacement if damaged and bead rolls are etched into the bead roll shaft for easy alignment.

Duct beading machine is a much faster practice as compared to the original cross breaking method.

A Duct Beading machine is a fairly simple machine where in you feed flat sheet metal into the machine and the machine forms 5 beads on 1300mm width sheet or 7 beads on 2000mm!!(depending on the machine model).

Main Features

1) Handwheels can be adjusted up and down, so that control the depth of the hook groove.

2) Suitable for 0.4-1.2mm galvanized steel coil, can be successful at one time.

3) Only one person can operate, it don't need a lot of people to operate.

4) The machine is widely used, and one machine can be used for many years.

More About Preda Machine Duct Beading Machine

Preda Duct Deading Machine is also named Duct Grooving Machine. It is used for making 5/7 line grooves with depth for prodcution HVAC duct in strengthen the air duct.

Preda Deading Machine has 6 handwheels for adjusting up and down in making grooving depth. Sheet mental beading machine has 2.2 kw power, it is suitable for 0.4-1.2mm galvanized steel, and can be successful at one time! Preda beading machines' standard voltage is 380v/220v, but we can still meet the voltage requirements of different countries. Preda grooving wheels are made high quality steel, after lots of processing techniques, it is then quenched to increase its hardness, it makes work well.

Preda duct beader machine is in duct making machines with a very high cost performance, which is very popular among European and American countries, and our price is very affordable.So it is a best choice when you plan to purchase a duct grooving machine/duct deading machine.

Flat workbench,The plate will enter and come out easily. Thickened panels make the machine run more stablily. Five rollers work together to make the hook groove easily.

Adjustable handwheel and thickened panel work together to make the groove of the hook meet production requirements.

The wheels and rollers of the hook groove are made of high-quality steel and are wear-resistant.

This is a very important step for HVAC duct production, and our machine will be of great help to you.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1.Are you factory or foreign trade company?

We are the manufacturer and do our own exporting team for more than 15 years' experience.

2.How can we operate the machine?

Our machines are very easy to operate.We have detailed installation and operating instructions attached.

We will arrange our engineers available to service machinery overseas for HVAC duct production lines.

3.How long warranty can you provide?

Our machine warranty is one year and life time service after sales.

4. What are your payment terms?

We support T/T, L/C, Western Union and so on. Other ways can also be received after we both sides discussion and agreement.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate