TDF flange forming machine T-12 -Preda Machine

TDF flange forming machine T-12 -Preda Machine

TDF flange forming machine T-12 -Preda Machine

- Detail

- Parameters

- Review

Product Application

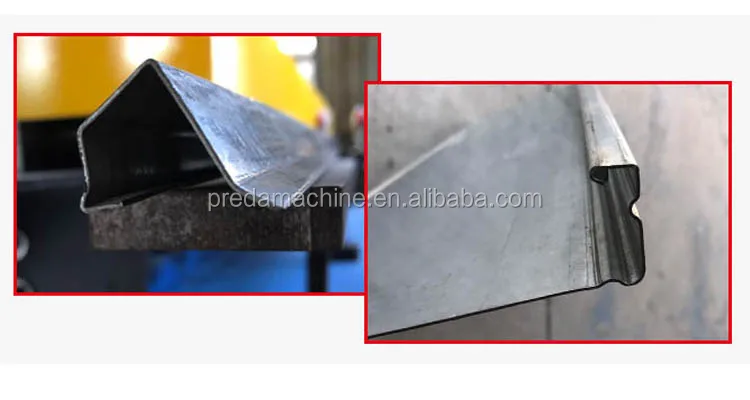

TDF flange forming machine, mainly used for making flange at edge of plate for further joint, is also among basic equipments for modern duct forming line.

All bearings used are ball bearings rather than traditional needle bearings so the machine more durable.

The flange shape made by the machine is nice and practical, which makes it a perfect part of duct forming line.

Preda Machine TDF roll former has two version, T-12 capable of 1.2mm and T-15 capable of 1.5mm galvanized metal sheet.

Main Features

T-12 is capable of maximum 1.2mm(18Ga) galvanized steel sheet while T-15 is capable of 1.5mm(16Ga) galvanized steel sheet or 1.0mm(20Ga) stainless steel sheet.

Preda Machine provides rollers and axles changing the whole life time of the machine.

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

More About T12 TDF Flange Forming Machine

In the TDF flange duct industry, the TDF flange machine is an indispensable equipment. The main function of the tdf flange machine is the forming of the duct flange and the forming of the flange clip.The TDF flange machine is suitable for 1.2mm galvanized HVAC duct production.

Preda Machine TDF flange machine is made of high quality 45# steel, it has good properties, high contact fatigue strength, good dimensional stability and corrosion resistance. After quenching and tempering, it has high hardness, uniform structure, good wear resistance and high contact fatigue performance. Preda Machine T12 tdf flange former has 2.2kw power, high power makes the forming of thicker plates better!

Preda Machine duct flange former can production effective duct flange and duct g clamp. They will make the ducts of different lengths fit very well and can be assembled into a very long duct.

About the maintenance of the tdf flange machine, the HVAC duct manufacturer also needs to pay attention. Usually, the iron removal on the tdf flange machine should be mentioned, and the lubricating oil should be regularly applied to the working roller wheels of the tdf flange machine to avoid the rust of the wheel due to long-term wear. If the tdf flange machine has abnormal noise after a long time of operation, it is necessary to check whether the bearing is damaged or not, and replace the bearing in time.

T12 tdf flange machine was carefully improved on the basis of the original Preda engineers. This is a great thing and contributed to the progress of the HVAC duct industry. It will be a great choose when you decided to purchase a high quality duct flange former.

The trolley is designed to hold a narrower sheet when machining the flange. Than push the trolley to move directly!

T-12

T-12 is capable of maximum 1.2mm(18Ga) galvanized steel sheet.

T-15

T-15 is capable of 1.5mm(16Ga) galvanized steel sheet or 1.0mm(20Ga) stainless steel sheet.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1.Are you factory or foreign trade company?

We are the manufacturer and do our own exporting team for more than 15 years' experience.

2.How can we operate the machine?

Our machines are very easy to operate.We have detailed installation and operating instructions attached.

We will arrange our engineers available to service machinery overseas for HVAC duct production lines.

3.How long warranty can you provide?

Our machine warranty is one year and life time service after sales.

4. What are your payment terms?

We support T/T, L/C, Western Union and so on. Other ways can also be received after we both sides discussion and agreement.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate