CNC press brake machine - Preda Machine

CNC press brake machine - Preda Machine

CNC press brake machine - Preda Machine

- Detail

- Parameters

- Review

2 years warranty Sheet Metal Bending Machine 3 meters Preda NC Sheet Metal Folding Machine

2 years warranty Sheet Metal Bending Machine 3 meters Preda NC Sheet Metal Folding Machine Products Description

Products Description

The hydraulic bending machine comprises a bracket, a worktable and a clamping plate, the worktable is placed on the bracket, the worktable is composed of a base and a pressure plate, and the base is connected with the clamping plate through a hinge, the base is composed of a seat shell, a coil and a cover plate, and the coil It is placed in the recess of the seat shell, and the top of the recess is covered with a cover plate. When in use, the coil is energized by the wire, and after the power is applied, the platen is attracted to the platen, thereby clamping the plate between the platen and the base. Thanks to the electromagnetic clamping, the pressure plate can be made into a variety of workpiece requirements, and the workpiece with the side walls can be processed.

| Model | Normal Pressure (KN) | Worktable length (mm) | Distance between holes (mm) | Depth of throat (mm) | Ram travel (mm) | Max. opening height (mm) | Main power (kw) | Weight (kg) | Overall dimension (LxWxH) mm |

| 40T/1600 | 400 | 1600 | 1150 | 230 | 100 | 320 | 5.5 | 2750 | 2200x1200x1910 |

| 40T/2500 | 400 | 2500 | 1850 | 230 | 100 | 320 | 5.5 | 3000 | 2500x1200x1910 |

| 50T/2500 | 500 | 2500 | 1850 | 230 | 100 | 320 | 5.5 | 3400 | 2500x1210x2000 |

| 63T/2500 | 630 | 2500 | 1900 | 250 | 100 | 320 | 5.5 | 4000 | 2500x1300x2210 |

| 63T/3200 | 630 | 3200 | 2560 | 250 | 100 | 320 | 5.5 | 4800 | 3200x1300x2210 |

| 80T/2500 | 800 | 2500 | 1990 | 300 | 100 | 320 | 7.5 | 5700 | 2500x1400x2300 |

| 80T/3200 | 800 | 3200 | 2560 | 320 | 100 | 350 | 7.5 | 6020 | 3200x1500x2300 |

| 80T/4000 | 800 | 4000 | 3000 | 320 | 100 | 350 | 7.5 | 7000 | 4000x1500x2300 |

| 100T/2500 | 1000 | 2500 | 2020 | 320 | 120/150 | 320/350 | 7.5/11 | 6000 | 2500x1600x2400 |

| 100T/3200 | 1000 | 3200 | 2600 | 320 | 120/150 | 370/400 | 7.5/11 | 6800 | 3200x1600x2600 |

| 100T/4000 | 1000 | 4000 | 3000 | 320 | 120/150 | 370/400 | 7.5/11 | 8400 | 4000x1600x2700 |

| 125T/3200 | 1250 | 3200 | 2580 | 320 | 120/150 | 370/400 | 7.5/11 | 7200 | 3200x1600x2600 |

| 125T/4000 | 1250 | 4000 | 3000 | 320 | 120/150 | 370/400 | 7.5/11 | 8800 | 4000x1600x2700 |

| 160T/3200 | 1600 | 3200 | 2600 | 320 | 200 | 460 | 11 | 10500 | 3200x1700x2700 |

Main Features

(1) Hydraulic transmission, the oil cylinders at both ends of the machine are placed on the slider to directly drive the sliding work.

(2) It adopts mechanical block structure, which is stable and reliable.

(3) The slider stroke is maneuvered quickly, manually fine-tuned, and the counter is displayed.

(4) It adopts all-steel welded structure with sufficient strength and rigidity.

(5) The slider synchronization mechanism uses the torsion axis to force synchronization.

(6) Oblique wedge compensation mechanism to ensure high bending accuracy.

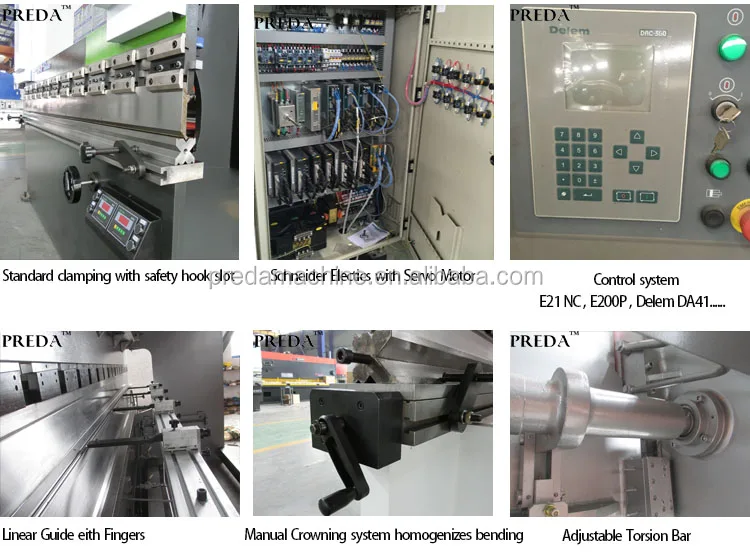

Main Configuration for Hydraulic Bending Machine series

(1) Estun E21 NC control system/ Delem DA41 CNC control system and other system from Preda.

(2) Powered Depth Y-axis & Back gauge X-axis.

(3) DELTA Inverter controlled back gauge/ Servo motor controlled back gauge.

(4) HIWIN Ball screws & Polished rod with 0.01/0.05mm accuracy.

(5) Plate Support Arms.

(6) Germany Bosch-Rexroth Hydraulic.

(7) Germany EMB Tubing connector.

(8) Germany Siemens Main Motor.

(9) Telemecanique/ Schneider Electrics.

(10) Hydraulic & Electrical overload protection.

(11) Top and Bottom Tooling (86°,R0.6mm)

(12) Manual Crowning system homogenizes bending.

The transport cost as reference please contact us to get more clearly transport cost directly. Different port of countries will have different cost!

Anhui Preda Machinery Manufacturing Co., Ltd. is a manufacturing plant, and produces and sells machinery, machine tools, machine tools, machine tools and machinery parts. It has many years of production experience and export experience. The products are sold to Europe, Middle East, Asia, etc. Countries in each region are unanimously recognized by customers.

Our company's equipment includes ventilation equipment, hydraulic shearing machines, bending machines, punching and shearing machines and other equipment for industrial production. A wide range of products to meet the different needs of customers also supports the customization of personalized machines according to customer requirements.

| FAQ |

| 1. How to get a accurate quotation from Preda Machine? |

| Provide the machine name you want, the specifications you need and the quantity of machine, we shall quote accordingly! |

| 2. What's the shipping cost from China to your country? |

| Please kindly tell us your nearest port to your place. We have reliable shipping forwarder to insure cheap, safe, convenient and timely delivery via sea. |

| 3. Payment terms, MOQ, warranty, FOB. |

Payment terms: 20% TT paid in advance, the balance of 80% before the shipment. |

| 4. What's the package? |

| 20'' container, 40'' container, wooden case, wooden tray.... |

| 5. What about commissioning service? |

| We can offer commissioning service, the buyer need to pay for all the transport, salary, hotel, meals for Preda Machine technicians caused during the service period. |

| 6. What's policy for guarantee and broken parts? |

| Warranty period of equipment is two years, during which the broken parts and spares caused by quality can be offered free. After guarantee period, all broken parts or easy wearing parts will be charged in a most competitive price ever in the market! |